Wood, Plastics, and Composites

1/Wood, Plastics, and Composites

-

Maintenance of Wood, Plastics, and Composites

Dust builds on the wood's surface over time, making it harder to clean. As a result, sweeping or mopping the floor daily, or at least on a regular basis, with only a soft broom or microfiber mop to avoid scratching the surface, is a basic advice for proper wood maintenance.

Flushing fresh water across the surface and then gently removing any particles stuck to the surface with your hand is the best approach to clean plastic surfaces. If necessary, a soapy water solution might be employed. When cleaning plastic, use a cloth with caution to avoid particles becoming stuck in the cloth.

-

Conservation Treatment for Period Wood

Copper azole is a water-based wood preservative that resists fungal deterioration and insect assault. Water-based preservatives, such as copper azole, dry to a clean paintable surface and can be used for periodic wood preservation treatment.

-

Common Work Results for Wood, Plastics, and Composites

Wood, plastic, and composite materials can be mixed to achieve a specific aim; however, certain types must be chosen to achieve the combined work of wood, plastic, and composites.

-

Schedules for Wood, Plastics, and Composites

Schedules for wood, plastic, and composite materials have been constructed due to the great number of types of wood, plastic, and composite materials available. These tables assist in the selection of the best types for their needs and the processing of wood, plastic, and composite materials.

2/Rough Carpentry

-

Wood Framing

Pine, fir, and Douglas fir are flexible softwoods with a straighter grain than hardwoods, giving them better strength and making them a popular choice for lumber framing. The quantity of faults in the wood determines the grade of sawn lumber, which indicates its quality.

-

Structural Panels

Wood structural panel sheathing keeps the house's structural integrity while also allowing for wall insulation, resulting in high-strength wall systems that are both affordable and simple to construct.

-

Heavy Timber Construction

Heavy timber construction as a system with major frame members no smaller than eight inches by eight inches in size and non-combustible external walls.

-

Treated Wood Foundations

Treated wood foundations are load-bearing, pressure-treated lumber frame walls that support light frame construction below grade. Permanent wood foundations, often known as all-weather wood foundations, are made of treated wood.

-

Wood Decking

Redwood, cedar, and pressure-treated wood, which can be constructed from several types of wood, are popular choices for wood decking. Both redwood and cedar are naturally pest and mildew resistant and have a natural appearance, but they also have their own set of problems.

-

Sheathing

The majority of ceiling owners these days prefer OSB, unless they're working with a heavier material like boards or concrete ceiling tiles, in which case plywood is usually a better choice.

-

Shop-Fabricated Structural Wood

Shop-produced structural lumber, such as manufactured (or engineered) wood flooring with a top layer of real wood (commonly referred to as wood veneer), is formed of composite wood, which is made up of multiple pieces of wood that have been bonded and pressed together.

-

Glued-Laminated Construction

Structure laminated with glue, also known as glued plywood (glulam), is a structural material manufactured by glueing individual sections of wood together with industrial adhesives (typically melamine or polyurethane adhesives), allowing for enormous pieces and distinctive shapes.

3/Finish Carpentry

-

Millwork

Millwork building materials are any goods made by wood mills for use in the construction of structures in the past. Synthetics, plastics, and wood-based adhesives all fall within this category.

-

Prefinished Paneling

Precast panels is a broader term referring to decorative panels used as follows:

A. decorate the wall

B. isolation

C. To prevent (and cover up) damage to walls, they are usually made of wood, covering three or four feet of an interior wall.

-

Board Paneling

A shingle (also known as a sideboard, skirting, plank, plank, floor moulding, or roofing) is a wood or vinyl plank that covers the bottom of an interior wall in architecture.

4/Architectural Woodwork

-

Architectural Wood Casework

Architectural woodwork, often called as architectural mills, is custom-made timber that is left visible inside a structure after construction, whether residential or commercial.

-

Wood Paneling

Wood panelling, like other aspects of home décor, has come and gone. Regularly criticised and often replaced from the 1980s onwards, wood panelling is now back in fashion, albeit in a modified version.

The most popular type of wood panel used for interior walls is Medium Density Fibreboard (MDF).

-

Wood Stairs and Railings

The cost of a 25-foot handrail might range from 700 pounds to 6000 pounds or more, depending on the type of material used. For example, the cost of installing metal stair railings varies between 3,500 and 6000 pounds, whereas the cost of installing wood handrails varies between 750 and 1250 pounds.

-

Ornamental Woodwork

Woodwork is utilised both indoors and outdoors for a variety of structures, and provides something unique that supports a rich aesthetic.

-

Wood Trim

The house's baseboard is a beautiful and functional sort of wood trim that runs at the base of the walls, hence the name "baseboards" or "base moulding."

-

Wood Frames

Hardwoods include walnut, oak, and teak, while softwoods include pine, oak, and basswood frames, the latter of which is one of the most cost-effective wood frame possibilities. Hardwoods are one of the greatest types of wood for photo frames.

-

Wood Screens and Shutters

Shutters and shingles are a flat, rectangular component that makes a raised, hollow, or framed portion of the surface on which they are installed, and are installed between two columns in the space or partition of the fence or railing.

5/Structural Plastics

-

Structural Plastic Shapes and Plates

Each approach is designed to produce a specific type of plastic shape. Plastic structural shapes and panels are particularly shaped plastic bodies that have gone through the plastic forming process. Molding, extrusion, casting, and other procedures are examples of plastic forming processes. Plastic panels, for example, are manufactured. Plastic structural assemblies fittings are made up of pieces that are added to plastic dechin to make them easier to install.

6/Plastic Fabrications

-

Simulated Stone Fabrications

Created gemstones are gemstones formed from the same original components as imitation gemstones, but created in a lab rather than taken from the earth. Imitation gemstones are gemstones made in a lab using materials that differ from the chemical composition of the gem it utilises as a substitute.

While gemstones are a lovely addition to jewellery, some people fear that they don't know enough about them to buy them with trust. With so much uncertainty on the market, it's critical to understand the difference between real and imitation stones.

-

Plastic Railings

Plastic fenders are stronger than wooden fenders when produced of superior commercial quality vinyl; in fact, vinyl fenders provide outstanding impact protection and wind resistance.

-

Plastic Paneling

PVC panels elevate wood panelling to a new degree of sophistication. It comes in a variety of colours and patterns to suit your own taste. Unlike wood panelling, it does not warp or rot. For high-traffic and crowded areas like kitchens and bathrooms, it also provides an easy-to-clean surface.

-

Plastic Trim

PVC is the most often used material for making plastic trim; PVC ornamental goods are linear extruded profiles that may be extruded to any length; plastic trim has a wide range of applications due to its abilities to hold, grip, protect, and seal.

-

Custom Ornamental Simulated Woodwork

The custom decorating imitation woodwork has a wood grain texture with many different material colours to select from, making it a popular choice for restaurant covers. Its lovely wooden look will enhance the restaurant's display.

7/Structural Composites

-

Structural Composite Shapes and Plates

Carbon fibre is a reinforcement in a polymer matrix composite, and composite panels and forms are usually the structure of the composite, with one component being the matrix and the other components being matrix-bound fillers.

-

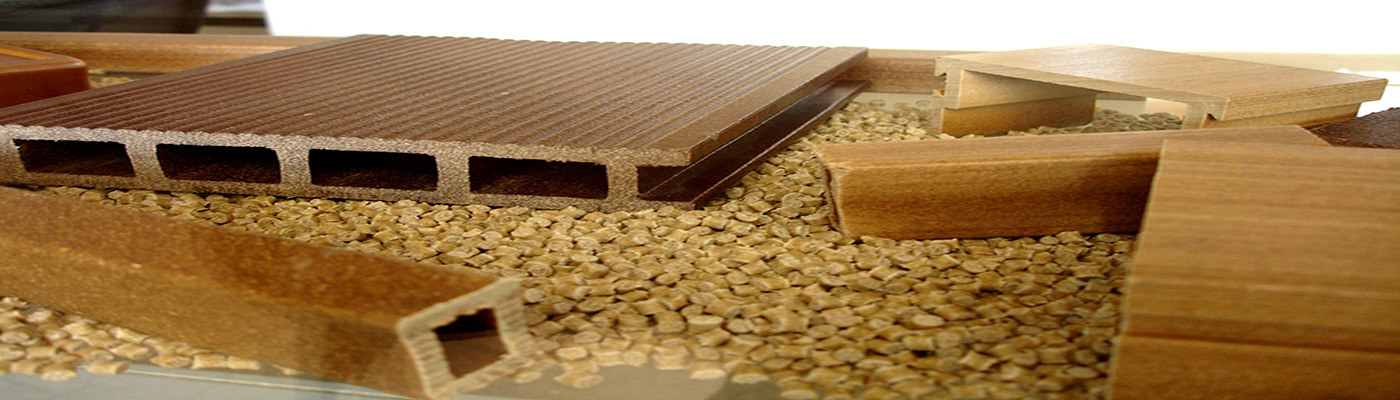

Composite Decking

There's no denying that composite decking materials are more expensive than wood, but they're prized for their incredible resemblance to natural wood and their efficiency, which makes them an excellent choice for decking. They're also easier to clean and maintain, which means they'll last longer and provide homeowners with the same value.

-

Composite Gratings

Glass fibre reinforced plastic grating (sometimes referred to as FRP grating, glass reinforced plastic grating, or fibreglass grating) is a composite grating made from a resin and fibreglass matrix.

8/Composite Fabrications

-

Composite Railings

Vinyl railings are often less expensive than composite railings, however some individuals find vinyl to be less aesthetically pleasant than composite railings, thus even if they appear to be the same from afar, composite railings feel more natural to them.

-

Glass-Fiber-Reinforced Plastic

Fiberglass is used in industry to improve mechanical strength, resist external damage, and keep a stable shape.

-

Composite Trim

While solid wood is still the most common material for exterior finishing, its flaws have created major opportunities for other goods. Builders who don't want to use wood often choose for edges made of cellular PVC, wood composite, or fibre cement. Because it is less sensitive to moisture changes than wood, it can keep paint on for longer. There is little waste because each one is of same quality and density. Finally, because composite trim is more resistant to water, fungi, and insects than solid wood, it is preferable to wood.

-

Composite Pergolas

Most of the pergolas you see are either wood or vinyl, however there are also metal and fiberglass pergolas or composite pergolas.

Please Login to Post a Comment

Login Register